Do you know who developed the first power supply system? Let the answer light up like a bulb in your mind. Yes, it was Thomas Edison! He did it in New York City in 1882. He used copper rods, which were covered in jute and positioned in rigid pipes containing a bituminous compound.

Well, the journey of an electrical power cable from then till now has been interesting with lots of changes, to be precise, improvements.

Modern power supply

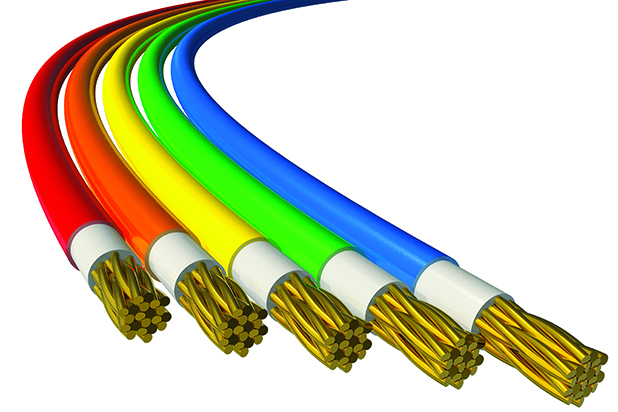

Modern cables for power supply are available in various types, materials, and sizes. Each one is designed based on the usage. Sometimes, big single insulated conductors are also known as cables in the electrical industry.

Components of electrical power cables

There are 3 chief components:

- Conductors

- Insulation material

- Protective layering

The design of each cable varies depending on its application.

How a cable is designed and what material is used depends on:

- Current carrying capacity of the cable – It determines the conductor’s cross-sectional size.

- Working voltage – It determines insulation thickness.

- Environmental conditions – They include temperature, mechanical force on cable, exposure to chemicals and sunlight, and exposure to water. They determine type and composition of outer protective layering.

Short circuit rating

Usually, size of conductor required for power supply inside cable is determined more by its capacity to transfer short circuit current than by its capacity to transfer sustained current. This is because during a short circuit a sudden gush of electric current passes for a few cycles. This is followed by a steadier current flow. The period ranges generally between 0.1 to 0.3 seconds. This is where the importance of material used to create electrical power cable comes to play. The material should withstand the sudden gush of current with minimum or nil damages or hazard.

Current carrying capacity and voltage drop

The capacity to carry current answers the question as to what size of conductor should be. It is the highest permissible rise in temperature that dictates the safe current carrying capacity of a cable, especially an underground one.

Voltage drop determines design of conductor for a power cable. Manufacturers consider the maximum permissible drop in voltage from source to load to design a cable conductor.

Here, Ohm’s law comes to play that states that current passing between two points in a conductor is directly proportional to voltage present across both points.

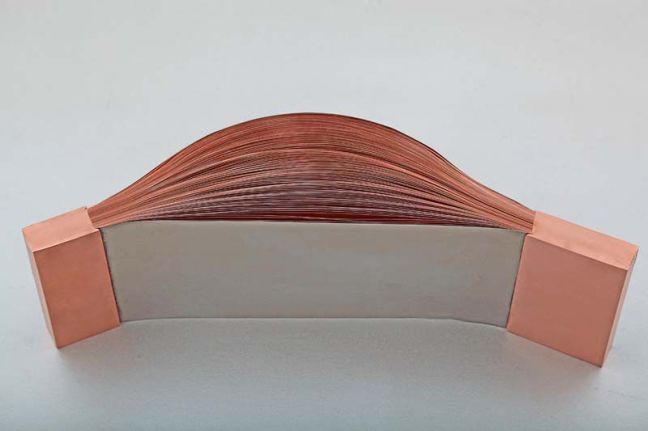

Choice of material is important here. Undoubtedly, copper is the best choice to manufacture electrical power cable. Copper wire is an efficient conductor and features lower voltage drop for a particular size and length than aluminum wire. Again, larger sizes of wire show lesser voltage drop than smaller sizes with the same length.

While choosing a cable you must know power requirements, application, voltage conditions, and such things. These will determine what type of cable will suit your electric power needs. Reputable manufacturers like Rajasthan Electric provide excellent wires and cables that are tested to the core and produced keeping in mind quality standards. You can also get braided connectors, tin coated copper wires, enameled copper strips, nickel copper wires, and more from them.